- Main Page

- Album of technical solutions

Self-locking mechanism for fixing the material strip: RF patent No. 107713

The utility model relates to the field of processing strip materials, in particular to the processing of metals by pressure, as well as to machines for rolling strips, namely, spools for winding strips of material.

The technical solution eliminates all the disadvantages available in analogues and, in addition, is cheap and easy to manufacture and use. Moreover, the self-locking mechanism for fixing the strip of material is rational to use on already working mills, changing only the design of the spool, which is possible in most cases.

When using this technology, due to the design features of the spool, a characteristic defect is formed - transverse pressure. This defect occurs due to the impact of the band clamping mechanism installed in the spool, which creates irregularities on the spool - dimples or cavities.

Technical results achieved when using the claimed utility model:

- — reducing the number of defective metal strips;

- — improving the reliability of fixing the end of the strip;

- — increasing wear resistance;

- — improving reliability;

- — improving serviceability.

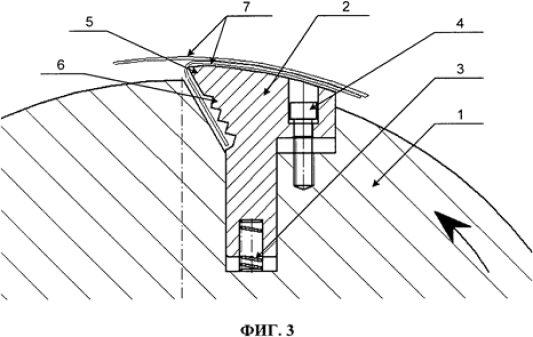

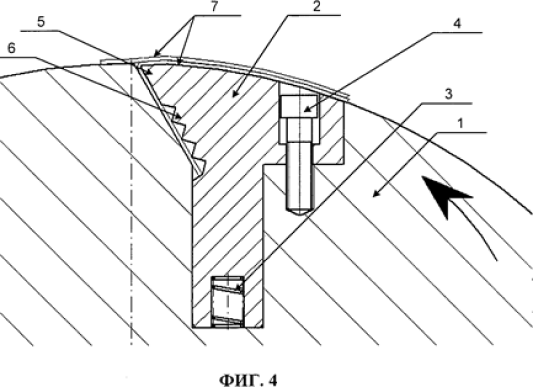

Technical results are achieved due to the fact that in a self-locking mechanism for fixing a strip of material containing a drum mounted with the possibility of rotation to ensure the winding of a strip of material on the surface of the drum, the envelope of the drum is a cylindrical surface, a mortise is made on the outer surface of the drum, an element is placed in the mortise with the possibility of moving along the mortise with access to the cylindrical surface of the drum, spring-loaded relative to the drum, a gap is formed between the side surface of the spring-loaded element and the inner surface of the mortise to accommodate the end of the strip of material, the height of the spring-loaded element is no more than the depth of the drum. The outer surface of the specified spring-loaded element, which extends to the cylindrical surface, is a part of the cylindrical surface with a radius corresponding to the radius of the envelope of the drum.

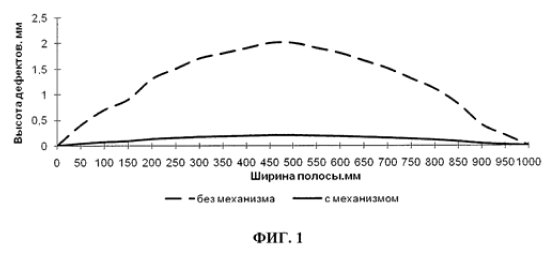

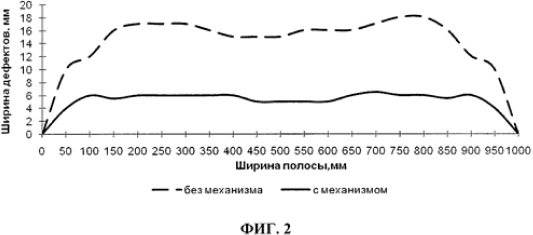

Tests have shown that the spools (drums), according to the claimed solution, allow you to get the metal with the least amount of defect - transverse pressure.

The height of the transverse boost when using the claimed solution decreased by about 10 times compared to the spool of the first type.

Self-locking mechanism for fixing the material strip

Pic.1 shows a graph of measurements of prints from the spool (the height of the irregularity relative to the strip itself). A solid line in pic.1 shows a graph of the height of defects on a roll of material rolled according to the claimed solution. The dotted line shows a graph of the height of defects when rolling a roll of material simply with a slot without using a self-locking mechanism.

Pic.2 shows a graph of measurements of the width of the prints from the spool. A solid line in pic.2 shows a graph of the width of defects on a roll of material rolled according to the claimed solution. The dotted line shows a graph of the width of defects when rolling a roll of material simply with a slot without using a self-locking mechanism.

Pic.3 shows a cross-section of the claimed self-locking mechanism for fixing the strip of material in the raised state.

Pic. 4 shows a cross-section of the claimed self-locking mechanism for fixing a strip of material in a compressed state.